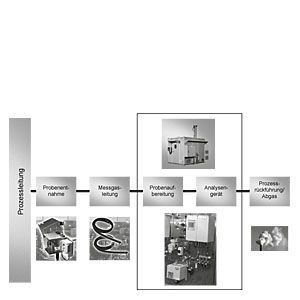

Siemens process gas analyzers have been used in the process industry for more than 40 years, and are renowned for their quality, reliability and accuracy. The flexibility provided by the continuous process gas analyzers with respect to housing design, explosion protection, corrosion resistance and communications capability means that optimum solutions can be found for all applications. Nowadays, the communications capability of analyzers is becoming increasingly important. Siemens process gas analyzers are an integral component of Siemens’ "Totally Integrated Automation" concept which is globally unique. This concept permits design of uniform process communication from the operations management level down to the field level. The simple integration of analyzers into the host control systems is the basis for a uniform automation and analysis solution. Many years of experience in the development and production of analyzers as well as in the planning and installation of analyzer systems distinguishes Siemens as a solution provider - reliable, innovative and with global presence. Schematic representation of the measuring setup of extractive site installations Extractive procedures for process gas analysisExtractive process gas analyzers are used for continuous determination of the concentrations of one or more gases in a gas mixture. Determination of the concentration of gases in a process is used to control and monitor process flows, and is therefore decisive for the automation and optimization of processes and ensuring product quality. In addition, process gas analyzers are used to check emissions, thus making an important contribution to environmental protection, as well as for ensuring compliance with statutory directives. With extractive measuring procedures, the sample to be analyzed is extracted from the process line and applied preconditioned to the analyzer via a sample line and a sample preparation system. This system, for example, adjusts the pressure, temperature and flow of the sample, and frees the sample gas of dust and moisture if necessary. This guarantees that the measurement can be carried out under defined conditions. Furthermore, the analyzer is protected from damaging influences. Various measuring procedures with different physical and electrochemical methods are used depending on the type of components to be measured and the measuring point. Siemens offers a range of measuring procedures for extractive gas analysis in two types of devices, SIPROCESS GA700 and Series 6 / ULTRAMAT 23. Each type of device provides peak analytical performances for its class. SIPROCESS GA700The SIPROCESS GA700 range is the latest generation of Siemens gas analyzers, and features a modular design. Up to two modules can be used per base unit. Base unit The base unit is available in three models: As a 19" rack unit with 3 height units, in a housing for wall mounting, and as an Ex d field device. The communication interfaces present in the base units can be adapted to the respective process environment or the process control system using additional optionally available electronics modules. Modules Depending on the measuring task, the SIPROCESS GA700 can be individually adapted to the respective analytical or process requirements by fitting selectable modules.

Field control unit The field control unit with Ex-d explosion protection and flameproof enclosure is approved for use in Zone 1 (ATEX / IECEx approval). Together with the OXYMAT 7 analyzer module it can be used for measuring the oxygen content of flammable or non-flammable gases. Series 6 / ULTRAMAT 23The classic analyzers from Siemens, Series 6 and ULTRAMAT 23, have been proven at our customers all over the globe in many years of use. ULTRAMAT 6 For highly-selective measurement of infrared-active components such as CO, CO2, NO, SO2, NH3, H2O, CH4 and other hydrocarbons. The ULTRAMAT 6 is a high-end analyzer in 19" format or in a sturdy field housing for use in harsh atmospheres. In general, the field of application ranges from all types of emission measurements to use in processes. These serve to control production processes and guarantee product quality, even in the presence of highly corrosive gases. ULTRAMAT 23 The ULTRAMAT 23 is an innovative multi-component gas analyzer for measuring up to three infrared-sensitive gases using the NDIR principle. Measurement of oxygen (O2) is also possible through the use of electrochemical oxygen sensors or measuring cells operating according to the paramagnetic principle ("dumbbell"). The use of an additional electrochemical H2S measuring cell permits use in biogas applications. ULTRAMAT/OXYMAT 6 For combined measurement of infrared-active components and oxygen in complex applications. OXYMAT 6 For measurement of oxygen concentration according to the paramagnetic principle in complex applications. The OXYMAT 6 measures oxygen according to the paramagnetic alternating pressure principle. This guarantees absolute linearity and allows the use of very small measuring ranges from 0 to 0.5% (detection limit 50 vpm), up to 0 to 100%, and even 99.5 to 100% in one unit. OXYMAT 61 For measurement of oxygen concentrations according to the paramagnetic principle in standard applications. Ambient air can be used as the reference gas for OXYMAT 61. This is supplied by a pump integrated in the analyzer housing. OXYMAT 64 For measurement of oxygen concentrations in the trace range by means of ZrO2 sensors. The OXYMAT 64 can be used to measure very small traces of oxygen, down to the smallest measuring range of 0 to 10 vpm. This is particularly interesting in systems for air separation. A catalytically inactive ZrO2 sensor or a catalytically active ZrO2 sensor can be selected, depending on the application. CALOMAT 6 For determining the concentration of hydrogen and inert gases in digital mixtures through measurement of thermal conductivity. The CALOMAT 6 features a high dynamic measuring range (e.g. 0 … 1% and 0 … 100% H2, configurable) and a short T90 time. CALOMAT 62 The CALOMAT 62 is a thermal conductivity analyzer that has been specially designed for applications with corrosive gases. It is possible to directly measure the concentration of gas components such as Cl2, HCl and NH3, as well as e.g. H2 and N2 in a corrosive atmosphere. FIDAMAT 6 For measurement of total hydrocarbons according to the flame ionization principle. SIPROCESS UV600 Gas analyzer based on UV resonance absorption spectrometry for measuring even very low NO, NO2, SO2, and H2S concentrations. General informationIntroducing flammable gases Introducing frequently or permanently explosive gas/air mixtures to the gas analyzers mentioned in this chapter is not permitted. The introduction of gases with flammable components at concentrations above the lower explosive limit (LEL) should only be carried out with analyzers fitted with piping. Purging of the housing as well as further measures must be carried out depending on the application. When using SIPROCESS UV600, please contact the technical department. An inert gas must be used for purging (see manual for further information). Cross-sensitivity Exact measurement results with regard to the technical specifications can only be expected if a sample gas is free to the greatest possible extent of gases exhibiting a cross-sensitivity with the measured component. The influences of these interfering components can be reduced using various measures. Please contact our specialists if you have any questions. General installation guide and operating instructions

Calibration/adjustment The Series 6 analyzers (ULTRAMAT 6, OXYMAT 6, CALOMAT 6) as well as the SIPROCESS GA700 analyzers (ULTRAMAT 7, OXYMAT 7, CALOMAT 7) should be calibrated with zero and span gas at least every 14 days.

Note: With OXYMAT 6/61 and OXYMAT 7, the zero gas and the reference gas must be the same.

You can find details on FIDAMAT 6, OXYMAT 64 and ULTRAMAT 23 (AUTOCAL) in the chapters describing the respective device. Explosion protection Refer to the separate manuals, references and standards concerning the topic of explosion protection. |

| Êàòàëîã 2018 | Êàòàëîã 2017 | Êàòàëîã 2016 | Êàòàëîã 2015 | Êàòàëîã 2014 | Êàòàëîã 2013 | Êàòàëîã 2012 | Ñåðòèôèêàò | Êîíòàêòû | Êàðòà ñàéòà | Ïîèñê |