Reliable functioning of analyzers is of decisive importance for process control. It is necessary to record, correct and transmit measured values, to set and modify parameters, to check functions, to update calibrations, and to scan status signals e.g. for preventive maintenance. Communication between the operator and device is therefore an important part of process analysis, and the offered facilities have become a decisive performance feature of analyzers. Extractive continuous process gas analysisThe gas analyzers of Series 6 (ULTRAMAT 6, ULTRAMAT/OXYMAT 6, OXYMAT 6, OXYMAT 61, OXYMAT 64, FIDAMAT 6, CALOMAT 6, CALOMATá62) as well as the ULTRAMAT 23 offer the following communication options in addition to data transmission with analog and digital outputs:

The modular SIPROCESSáGA700 gas analyzer with the ULTRAMAT 7, OXYMATá7 and CALOMATá7 modules offers the following communication options in addition to data transmission with analog and digital outputs:

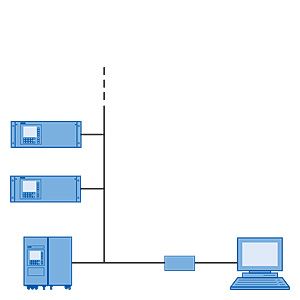

RSá485 interface The serial interface integrated as standard permits communication between several analyzers over the internal bus (ELAN). Parameterization is carried out using the analyzer's menu. Networking over ELAN ELAN communication is used e.g. for the interference gas correction of interfering gases. Direct connection is only possible between Siemens gas analyzers. Bus cable with plug connections, ELAN networking

Note If the cable is longer than 500ám or high interference effects are present, it is advisable to install a repeater on the device side. Networking with SIPROMáGA When used externally, the RS-485 interface requires software matched to the analyzers, e.g. SIPROM GA. SIPROMáGA is a software program for communication between a PC or laptop and analyzers. A maximum of 12 devices (electronics modules) with up to four channels/measured components of the following type can be connected, displayed and remote-controlled per COM interface:

SIPROMáGA allows access to device parameters all the way to the device configuration. All analyzer functions (except factory default functions) can be remote-controlled and monitored in this manner. SIPROMáGA is therefore an ideal service and maintenance tool for Siemens gas analyzers. In addition to remote control of all operator functions, SIPROMáGA offers full access to all diagnostic data. SIPROMáGA therefore permits preventive maintenance as well as fast responses when maintenance becomes necessary or when the production process is changed. SIPROMáGA guarantees:

In addition to the display of analyzers with TAG No., components, current measured values, comprehensive diagnostics information (status) and parameter assignment, SIPROM GA also offers the following possibilities:

Analyzers are accessed using SIPROMáGA in one of the following two ways:

Hardware requirements In order to use SIPROMáGA, the following hardware and system requirements for the PC/laptop equipment must be met:

Accessories for the network For cables, connectors, repeaters etc., see Catalog IK PI or in the Mall in CA 01 under SIMATIC NET communications systems / PROFIBUS / Network components. Networking with SIPROMáGA via converter A maximum of 12 analyzers with up to four components each can be networked. The functional principle is shown in the following illustration. Typical structure of an RSá485 Ethernet network via SIPROMáGA The gas analyzers can be installed at distances up to 500ám. One network can be connected to each COM port. Networking with SIPROMáGA via Ethernet For access via Ethernet, there are no limitations on the distance between PC and gateway. In addition, communication via Ethernet enables the installation of multiple gateways on one COM port. As a result, the possibility exists for operator control and monitoring of multiple analyzers or analyzer systems located far away and far apart from one station. Typical structure of an RSá485 Ethernet network via SIPROMáGA PROFIBUS The commonly used practice of transmitting measured values and fault messages via analog and digital outputs requires complex cabling. By contrast, with PROFIBUS DP and PROFIBUS PA, a single 2-wire cable is possible for digital transmission of, for example, all measured values (including from several channels), status information and diagnostics functions for preventive maintenance. The PROFIBUS DP version is widely used in production automation because of its high transmission rate for relatively small data quantities per device. PROFIBUS PA makes allowance, in particular, for the properties required in process industry, e.g. large data quantities and use in hazardous areas. The limited dynamic performance of 4áto 20ámA mA signals can be replaced, the laborious configuring of measuring ranges can be omitted. By using simulated measured values without media, increased safety can be provided for the plant configuration, and configuration errors can be avoided. Parameter sets can be generated offline (from your desk) and subsequently downloaded and saved in the device. Local operations can thus be reduced to a minimum. With an optional plug-in card, which can also be retrofitted, the following Siemens gas analyzers are PROFIBUS-compatible and comply with the mandatory "Device profile for analyzers" of the PI (PROFIBUS International).

Customer benefits include enormous savings potential in all plant areas, covering configuration and commissioning, operation and maintenance, up to subsequent plant expansions. Operation of the gas analyzers from a control system or a separate PC is possible with the SIMATIC PDM tool (Process Device Manager). The SIMATICáPDM software runs on Windows and can be integrated in the SIMATICáPCSá7 process control system. This permits a clear presentation for integration of the analyzers in the system as well as for the complex parameter structure of the analyzers. Direct connection of the analyzers to a control system without PDM, e.g. using STEP 7, is also possible but this requires additional programming and is less convenient for the operator. In most cases, this direct connection is therefore only applicable if acyclic (device operation) data are not used. A differentiation is made between cyclic and acyclic services. Cyclic services are used to transmit time-critical data such as measured values and statuses. The acyclic services allow device parameters to be queried or changed during operation. Both graphic displays and values can be output on a PC. Signaling of maintenance, fault and diagnostics information is also cyclic. These data are displayed in plain text when using SIMATICáPDM. The digital outputs can also be switched using cyclic services, thus also permitting triggering of relays over PROFIBUS (e.g. for measuring point switchover, calibration etc.). Schematic structure of a PROFIBUS system The following acyclic device parameters and device configurations can be used in PROFIBUSáDP and PROFIBUSáPA with SIMATIC PDM:

Use of PROFIBUS offers the following customer benefits:

Generic communications interface Users benefit from numerous functions that are mainly needed in the automotive industry, for example, to carry out repeated linearization. In contrast to PROFIBUS and ELAN, communication is only possible between one device and one PC, and takes place according to the master/slave principle. The device only transmits data when requested by a command telegram, where only one command can be processed and replied to at a time. Function88 can be used to open the generic communications menu and set the parameters. SIPROCESSáGA700: connection via ModbusáTCPDer SIPROCESS GA700 uses ModbusáTCP for interference gas corrections and for external pressures for measured value processing. Measured values such as process value, pressure and temperature can also be imported from other SIPROCESSÔÇĹGA700ÔÇÉdevices and shown on the display. The SIPROCESSáGA700 can simultaneously accept up to seven connections via ModbusáTCP.

The virtual digital inputs can be freely configured just like the physical inputs. As a result for example, it is possible to start an AutoCAL, set external errors and switch between various measuring ranges via ModbusáTCP. SIPROCESSáGA700: Possible communication pathsThe SIPROCESSáGA700 has two Ethernet interfaces: one process interface and one service interface.

The parameter assignment using SIMATICáPDM is also possible via a point-to-point connection with the SIPROCESSáGA700. Close-distance and long-distance remote access to the SIPROCESSáGA700 can also be set up using standard network components (WLAN access point / UMTS router / DSL router). The following figure shows a selection of possible communication paths and network components that the SIPROCESSáGA700 can use for communication. SIPROCESSáGA700: Communication paths and network components With a ModbusáTCP/PROFINET gateway, the SIPROCESSáGA700 can also be connected to a controller via PROFINET. Connection of two separate networks (e.g. multiple locations) via the Internet. A VPN tunnel is set up over the Internet between a UMTS router (plant environment) and an ADSL router (office environment). All SIPROCESSáGA700 devices can now be addressed from any node using, for example, SIMATICáPDM/controller/Modbus client in one of the two networks via ModbusáTCP and S7-400 (PDM). Remote access The WLANáaccessápoint enables mobile access to devices via a laptop, for example. If a PDM web server was installed and set up, you can access the SIPROCESSáGA700 devices from hand-held devices (mobile phone, tablet) via a web browser. The PDM web server is a computer on which SIMATIC PDM with additional web server functionalities is installed. In-situ continuous process gas analysisLDSá6 can send and receive data over an Ethernet connection with the help of the LDScom software. This installation and service tool is able to check and adapt device status and calibration parameters from a remote location. If necessary, even a complete system check can be carried out over the remote connection. If servicing is necessary, the required information can be sent to the Siemens service engineer by router, and he can then carry out the appropriate measures from the remote location. This facility for remote maintenance and diagnostics is implemented using a standard LAN modem. External connection of LDSá6 via a modem for implementing remote maintenance measures |

|||||||||||||||||

| ╩Ó˛ÓŰţŃ 2018 | ╩Ó˛ÓŰţŃ 2017 | ╩Ó˛ÓŰţŃ 2016 | ╩Ó˛ÓŰţŃ 2015 | ╩Ó˛ÓŰţŃ 2014 | ╩Ó˛ÓŰţŃ 2013 | ╩Ó˛ÓŰţŃ 2012 | Đň˛Ŕ˘ŔŕÓ˛ | ╩ţݲÓŕ˛ű | ╩Ó˛Ó ˝ÓÚ˛Ó | ¤ţŔ˝ŕ |