|

|

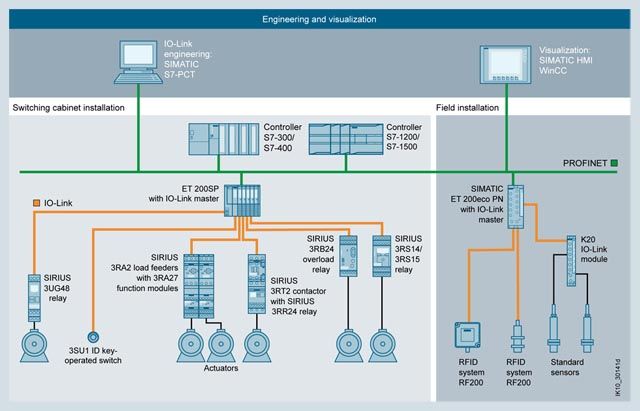

IO‑Link product family To implement the communication, a system installation has the following main components: - One IO-Link master

- One or several IO-Link devices, such as sensors (e.g. RFID systems), actuators or combinations of these

- A standard 3-wire sensor/actuator cable

Example of a configuration with the system components Compatibility of IO-LinkIO-Link ensures compatibility between IO-Link-capable modules and standard modules as follows: - IO-Link sensors can be operated both on IO-Link modules (masters) and standard input modules.

- IO-Link sensors/actuators as well as today's standard sensors/actuators can be used on IO-Link masters.

- If conventional components are used in the IO-Link system, then of course only the standard functions are available at this point.

Analog signalsAnother advantage of IO-Link technology is that analog signals are already digitized in the IO-Link sensor itself and are digitally transmitted via IO-Link communication. As the result, faults are prevented and there is no extra cost for cable shielding. Enhanced through IO-Link input modulesIO-Link compatibility also permits connection of standard sensors/actuators, i.e. conventional sensors/actuators can also be connected to IO-Link. This is particularly effective with the IO-Link input modules, which allow several sensors to be connected at one time via a cable to the controller. Overload relaysA starter combination, for example, consists of one or more SIRIUS 3RT contactors and one 3RB24 electronic overload relay plus its 3RB29 current measuring module. 3RB24 overload relays with IO-Link are basically designed to provide current-dependent protection for loads against inadmissibly high temperature rises due to overload, phase asymmetry or phase failure. Direct-on-line starters can, therefore, as shown in the image, be connected to the control system via IO-Link without much wiring. Remote control of connected contactors, current value transmission and immediate remote fault diagnosis are just some examples of the large number of functions that can be implemented with this device. It is also possible to directly address a drive on-site via IO‑Link using the optional hand-held device.  Connection of an IO‑Link-capable overload relay to a SIMATIC S7‑1200 controller Load Feeders and Motor StartersThrough IO-Link it is possible to control not only sensors but also actuators in the form of load feeders and motor starters.  Possibilities for connecting load feeders and motor starters to IO-Link or in the conventional way Monitoring relaysBy using monitoring relays with IO-Link it is now possible to send data that has already been recorded and evaluated in the devices directly to the controller. This avoids the use of duplicated sensors.  Possibilities of interfacing conventional 3UG46 monitoring relays (in comparison with 3UG48)  Possibilities of interfacing 3UG48 monitoring relays for IO-Link Wireless communicationUsing an upstream IWLAN client module, such as SCALANCE W722‑1 RJ45, allows IO-Link to be be integrated into the PROFINET world via a distributed I/O. Possible uses include acting as an alternative to fault-prone tow chain or collector wire technology. The individual diagnostics options offered by the various IO-Link devices provide greater transparency for the production process. Just like the parameter data for a device, these diagnostics data can be evaluated remotely using the possibilities offered by SIMATIC. This supports remote maintenance down to the lowest level in the field.  Wireless communication between Industrial Ethernet and IO-Link components IO-Link componentsIO‑Link master |

|---|

| | Masters |  SM 1278 4xIO‑Link for S7‑1200 | IO‑Link master for SIMATIC S7‑1200 - SM 1278 4xIO‑Link master signal modules

IO-Link master modules for ET 200SP - CM IO‑Link communication module

IO‑Link master module for ET 200pro - 4 IO‑LINK HF electronic module

IO‑Link master module for ET 200eco PN - IO‑Link master 4 IO‑L + 8DI + 4DO 24 V DC/1.3 A

- IO Link master 4 IO‑L

IO‑Link master module for ET 200AL - CM IO‑Link communication module

see "Master" | IO‑Link devices | | | | Detection with IO-Link |  K20 IO-Link modules | IO-Link input modules K20 input module - 4 inputs, M12 connections

- 8 inputs, standard M8 connections

see "Input modules" | | | Switching with IO-Link |  SIRIUS 3RA2711 function modules for IO-Link | Contactors and contactor assemblies SIRIUS 3RT contactors, 3-pole up to 250 kW SIRIUS 3RA23 reversing contactor assemblies, up to 55 kW SIRIUS 3RA24 contactor assemblies for wye-delta starting, up to 90 kW See "Industrial controls" → "Switching Devices" → "Contactors and Contactor Assemblies" → "Power Contactors for Switching Motors" SIRIUS 3RA27 function module - for direct-on-line, reversing, and star-delta (wye-delta) starters with IO-Link interfacing

See "Industrial Controls" → "Switching Devices” → “Accessories and Spare Parts” → “for SIRIUS 3RT2 Contactors and SIRIUS 3RH2 Contactor Relays” → “Modules for Contactor Control" |  SIRIUS 3RA64 direct-on-line starter | Motor starters for operation in the control cabinet SIRIUS 3RA64, 3RA65 compact starters for IO-Link - 3RA64 direct-on-line starters

- 3RA65 reversing starters

Infeed system for 3RA6 Accessories See "Industrial Controls" → "Load Feeders and Motor Starters → “For Use in the Control Cabinet" | | | Contactors with IO-Link |  SIRIUS 3RB24 overload relays | Overload relay SIRIUS 3RB24 solid-state overload relays for IO-Link - Evaluation module

- Current measuring modules from 0.3 to 630 A

- Controlling direct-on-line, reversing and star-delta starters via IO-Link in conjunction with contactors

- Full motor protection

- Diagnostics and current value transmission via IO-Link

See Industrial Controls → "Protective Devices" → "Overload relays" | | | Monitoring with IO-Link |  SIRIUS 3RR24 monitoring relays | SIRIUS 3RR24 monitoring relays for mounting onto 3RT2 contactors for IO-Link - Monitoring of current, phase failure, open circuit and phase sequence

- Designed for mounting on 3RT2 contactors

- Terminal supports for stand-alone installation

See "Industrial Controls" → "Monitoring and Control Devices" → "Relays" |  SIRIUS 3UG48 monitoring relays | SIRIUS 3UG48 monitoring relays for stand-alone installation for IO-Link - Monitoring the supply system, voltage, current, cos φ, residual current or speed depending on device design

- On/tripping delay time can be adjusted

See "Industrial Controls" → "Monitoring and Control Devices" → "Relays" |  SIRIUS 3RS14 temperature monitoring relay | SIRIUS 3RS14, 3RS15 temperature monitoring relays for IO-Link - Temperature monitoring with connected sensors

- Two limit values, can be adjusted separately

See "Industrial Controls" → "Monitoring and Control Devices" → "Relays" | | | Actuators and indicators with IO‑Link |  SIRIUS ACT ID key-operated switch 3SU1 | SIRIUS ACT ID key-operated switch 3SU1 for IO‑Link - Access and selection system for four authorization levels

- Authentication of user groups and persons

- Five ID codes with different coding

- Option of individual coding via IO‑Link

- For installation in enclosures or fastening on front plate

- Electronic module for ID key-operated switches must be ordered separately.

See "Industrial Controls" → "Commanding and Signaling Devices" → SIRIUS ACT "Pushbuttons and Indicator Lights" |  SIRIUS ACT 3SU1 electronic module | SIRIUS ACT 3SU1 electronic modules for IO-Link - Eight digital inputs and outputs possible

- DI and DQ freely selectable (programmable)

- Input and output functions parameterizable

- Connection system (push-in)

- For fastening on front plate

- For installation in enclosure

See "SIRIUS ACT pushbuttons and indicator lights" → "Modules for Actuators and Indicators" → "Electronic module for IO-Link" | IO-Link RFID systems |  RFID systems for IO‑Link | SIMATIC RF200 RFID system in the HF range Products SIMATIC RF210R, SIMATIC RF220R, SIMATIC RF240R, SIMATIC RF250R, SIMATIC RF260R - Simple identification tasks such as reading an ID number (UID)

- Read user data

- Writing of user data

- No RFID-specific programming, ideal for those new to RFID

- Simple connection via master modules for IO‑Link, such as SIMATIC S7‑1200, ET 200SP, ET 200pro, ET 200eco PN and ET 200AL

- Use with the tried and tested ISO 15693 transponders (MDS xxx)

see "Identification systems" | IO‑Link Device Description (IODD) | |  IODD files for IO-Link | IODD files They provide the device description for IO-Link devices |  IODDfinder for IO-Link | IODDfinder The entire world of IO under one roof The IODDfinder is a service provided by the IO-Link community. It is a central cross-vendor database for descriptive files (IODDs). In addition, the platform provides an overview of all IO‑Link devices. For more information see https://ioddfinder.io-link.com/#/. | IO‑Link software |  STEP 7 PCT | STEP 7 PCT (Port Configuration Tool) Engineering software for configuring the IO‑Link master modules for SIMATIC S7‑1200, ET 200SP, ET 200pro, ET 200eco PN and ET 200AL - Available as a stand-alone version or integrated into STEP 7 (V5.5 SP1 or later) and TIA (V12 or later)

- Engineering of the IO‑Link devices connected to the master

- Monitoring of the process image of the IO-Link devices

- Open interface for importing further IODDs

- Freely available to download from Industry Online Support; see https://support.industry.siemens.com/cs/de/en/view/32469496

|  IO‑Link device function block | IO‑Link function block (IO‑Link device and IO‑Link master) STEP 7 function block for easy acyclical data exchange in the user program |  “Siemens IO‑Link Devices” block library | “Siemens IO‑Link Devices” block library This library provides function blocks and user-defined data types (UDTs) for all IO‑Link devices from the Siemens portfolio. These blocks and UDTs standardize and simplify communication with IO‑Link devices. |

|

|