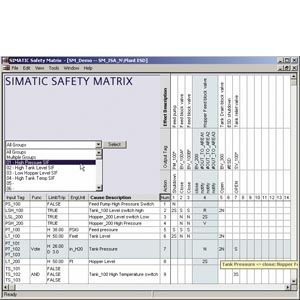

Safety Matrix: intersections define the linking of causes and effects The matrix table is comparable with a spreadsheet program, and the project engineer first enters the possible process events (inputs) in the horizontal lines, and then configures their type and number, logical links, possible delays and interlocks, and any tolerable faults. The reactions (outputs) to a particular event are then defined in the vertical columns. The events and reactions are linked by simply clicking the cell at the intersection of the row and column. Using these data, the SIMATIC S7 Safety Matrix automatically generates complex, safety-related CFC programs. The project engineer requires no special programming skills and can completely concentrate on the safety requirements of the plant. Input window for configuration of analog "causes" with process value preprocessing Each input value can be combined with a freely configurable preprocessing if necessary without giving up the simulation option. The alarm management is supported by collective alarms, alarm prioritization and individually adjustable acknowledgement. In addition to the alarms derived from process values, alarms can also be generated and diagnostics information can be provided for each individual cause and effect. Priorities and response behavior can be defined in various profiles here. The color scheme for the alarms and messages can be adapted on a customer- or country-specific basis. For the Safety Life-cycle Management, functions are integrated for the version management and for the documentation of program changes and operator interventions. During plant operation, the operator has direct access to the relevant data with the viewer of the SIMATIC S7 Safety Matrix. From the overall view it can change directly to cause or effect related detailed views and return from there. In the detailed views, alarm indications corresponding with the respective cause or effect can be called up. Tag display in online mode with process value, simulation value and active value The signal status is indicated online in the Cause & Effect matrix. The process value, simulation value and active value are indicated on the tag display in each case. The SIMATIC S7 Safety Matrix viewer enables the operator to display and save first value messages as well as to record safety-relevant events. Changes in parameters are supported, as are bypass, reset and override functions. |

| Каталог 2018 | Каталог 2017 | Каталог 2016 | Каталог 2015 | Каталог 2014 | Каталог 2013 | Каталог 2012 | Сертификат | Контакты | Карта сайта | Поиск |