|

| | | | | | |

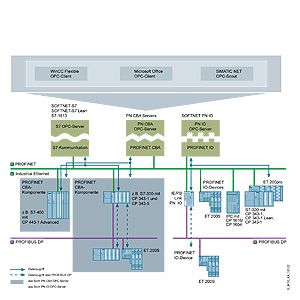

- The PN CBA OPC server communicates with PROFINET CBA components over Industrial Ethernet by means of DCOM protocol

- Open standardization of the addressing using logical names for objects from an automation component or an automation system

- Operation in parallel with other protocols is possible, such as

- S7 communication

- Open communication (SEND/RECEIVE)

- Efficient data transfer from a process component to an application for further processing:

- Synchronous and asynchronous reading and writing of variables

- Monitoring of variables using the OPC server with a signal to the client when a change occurs

- Use of quantity operations; a large amount of data can be processed in a short time.

- Simultaneous execution of more than one client is possible on one OPC server

- OPC Scout as an OPC client with browser functions for all interface variables of the PROFINET CBA components

User interfaces - "Custom Interface“ for high-performance C++/.NET applications

- "Automation Interface" for easily created Visual Basic applications (or similar)

- XML DA interface;

Data access to S7 CPUs is therefore possible over the Internet. - OCX Data Control for direct embedding in Windows applications that support COM/DCOM

Configuration - For configuring the PROFINET communication, a separate engineering tool SIMATIC iMap is required. This tool is offered as an option package with STEP 7.

- With SIMATIC iMAP, the communication links between PROFINET CBA components are graphically configured. In addition to the interconnection data, the engineering tool also creates the data used to access the interface variables over the PN CBA OPC server from visualization systems or office applications.

|

|