|

|

Controls made easy:

SIRIUS SIRIUS Planning EfficiencyWith Planning Efficiency, Siemens Industry has provided answers to typical questions that often come up in electrical planning: - What is the right product for my application?

- Where can I find product data?

- How can I design processes in a more efficient and time-saving way?

Planning Efficiency brings together the whole of Siemens Industry's electronic support. At each stage of the project, online functions make the everyday life of the planner easier through greater efficiency. At the same time, Planning Efficiency focuses on aspects such as optimization in the configuring of control cabinets. In this early phase in electrical planning in particular, savings of up to 80% can be made in time and costs.  To supply planners with everything they need and make modern electrical planning easier when configuring control cabinets, the electronic support provided by Planning Efficiency focuses on four advantages: - Get to the right product faster with intuitive product selection

- Time savings of up to 80% with universal product data for your CAE and CAD system

- User-friendly compilation of project-specific documentation

- Comprehensive support – anywhere, anytime

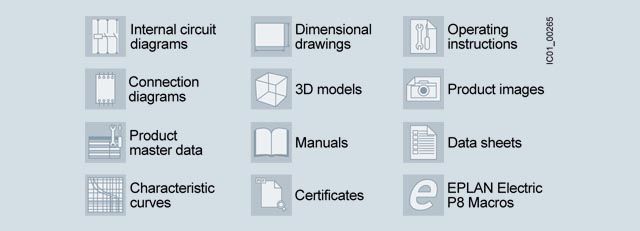

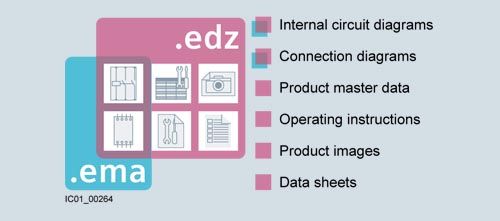

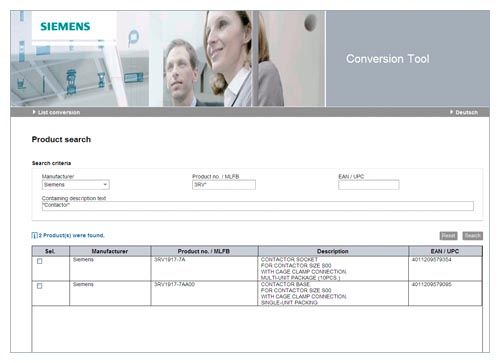

Process phases Siemens Industry provides comprehensive and free online functions in every process phase. Thus, all the information and product data you require are available worldwide and around the clock.  Configurators for products and systems In just a few clicks, the configurator will guide you to the right product or system for your requirements. Simply enter the relevant parameters and select your individual solution.  The configurator supplies the correct 3D models and dimensional drawings for the cabinet configuration diagram. CAx Download Manager In just four selection steps, the CAx Download-Manager provides you with all the necessary CAx data types for your desired products for use in all common CAE and CAD systems, free and up-to-date. You are then provided with an individual download package as a zip file for later use. This result in time savings of up to 80 %. Manual data gathering is no longer necessary thanks to universal manufacturer data for all common CAE and CAD systems.  The CAx Download Manager provides 11 universal data types and the EPLAN Electric P8 macro My Documentation Manager We have developed a manual configurator to support you in creating system documentation. With just a few clicks, standard-compliant system documentation can be individually compiled in My Documentation Manager. Simply choose the required sections from the existing manuals of the Siemens products installed. EPLAN Electric P8 macro - the benefits for EPLAN users The EPLAN Electric P8 macro (.edz format - EPLAN Data Archived Zipped) reduces the overall time required for data integration even further. With just a few clicks, the data types it includes for any number of article numbers can be imported, and they remain linked with one another. In this way, the installed Siemens products can be represented across different circuit diagram pages quickly and easily.  The EPLAN Electric P8 macro (.edz format) offers even more in comparison with the .ema format. At a glance Without Planning Efficiency a lot of time used to be wasted in manual data transmission. Now you can concentrate on the essentials again. All the information and product data you need are provided by Siemens Industry and, are easily accessible. This makes configuring control cabinets more efficient and makes your everyday work easier. For more information, see http://www.siemens.com/planning-efficiency.  Find out more about Planning Efficiency in descriptive videos From old to new - the new conversion tool Every automation system eventually becomes obsolete. Replacing installed products used to involve significant time and costs. But with the new conversion tool you can now find the suitable product faster – and easily make the switch to SIRIUS Innovations: - A user-friendly interface provides intuitive search options

- Simple entry of article numbers or descriptive texts for existing projects (e.g. *Contactor*)

- The search result provides you with the article number of the desired device, including current data and information on using the new product.

- Order conveniently from the Industry Mall

For more information, see

http://www.siemens.com/sirius/conversion-tool.  Controls made easy:

SIRIUS configuratorsWe offer a large number of configurators for the SIRIUS product spectrum. These facilitate the choice of suitable products and systems for your application. Simply choose the features you require and the optimum solution will be offered to you after only a few clicks. You can then order the products conveniently through the Industry Mall. For more information, see http://www.siemens.com/sirius/configurators. Detecting/signaling SIRIUS ACT pushbuttons and indicator lights - Put together individual operator controls or complete enclosures according to your wishes

- Select all combinations of pushbuttons, enclosures and switching elements individually

For more information on the SIRIUS ACT Configurator see

http://www.siemens.com/sirius-act/configurator.  SIRIUS 3SE5/3SF position switches - Selection of basic switch, actuator head, as well as a matching actuator can be performed in just a few clicks

- Combine individual elements to suit your requirements and assemble to create your individual variants

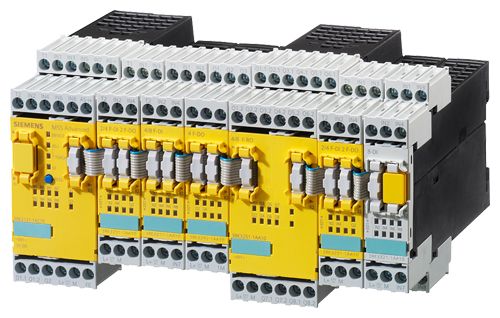

Evaluating SIRIUS 3SK safety relays - Fast and clear creation of safety-related applications (e.g. EMERGENCY-STOP and protective door monitoring)

- Simply enter the number of sensors or outputs and choose any accessories

- The configuration result provides you with article numbers and also technical data and 3D models for the matching products

3RK3 Modular Safety System - Freely parameterizable, modular safety relays

- Intuitive component selection

- Easy entry of the necessary inputs and outputs as well as the required communication options

- Matching accessories such as diagnostic displays or PC cables can be optionally added

Switching/protecting/starting SIRIUS Innovations system configurator - Easily find the right combination of motor starter protector/circuit breaker, contactor and matching accessories

- Enter motor data and your required features

- The configuration result provides you with all the necessary article numbers as well as technical documentation and 3D models for engineering

- Also possible for more complex structures such as 3-phase busbar systems and complete infeed systems

SIRIUS 3RM1 motor starters - Put together an individual motor starter or a complex motor starter group

- Individual options such as direct-on-line or reversing start, spring-type or screw terminals and also motor current and control voltage

- Graphical display of the structure during configuration

- Automatic determination of the suitable circuit breaker (group configuration)

SIRIUS 3RA6 compact starters and infeed system for 3RA6 - Easy to use – from individual compact starters or also with associated infeed system and AS-i interfacing

- The configuration result provides you with additional technical information such as CAD data and product data sheets as well as characteristic curves, operating instructions, manuals and much more.

SIRIUS 3RW soft starters - Easy and fast selection of suitable soft starters

- Note:

For correct dimensioning of the soft starter, you should use the Win-Soft Starter tool. The configurator contains the link to the software.

SIRIUS 3RF solid-state switching devices - Easy selection of individual solid-state switching devices on the basis of technical features (e.g. zero-point switching, spring-type terminal and rated current)

- The configuration result provides you with the article numbers for the matching products

Controls made easy:

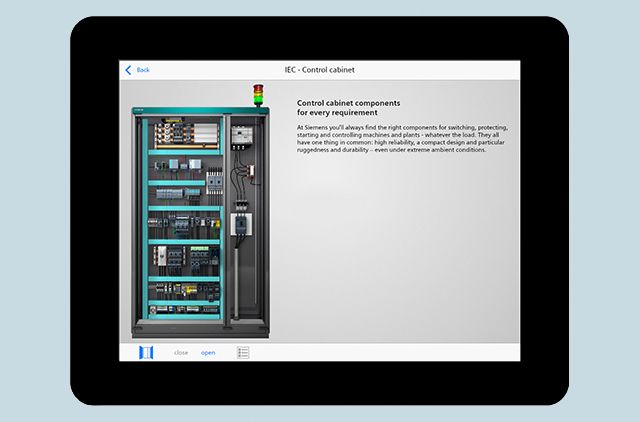

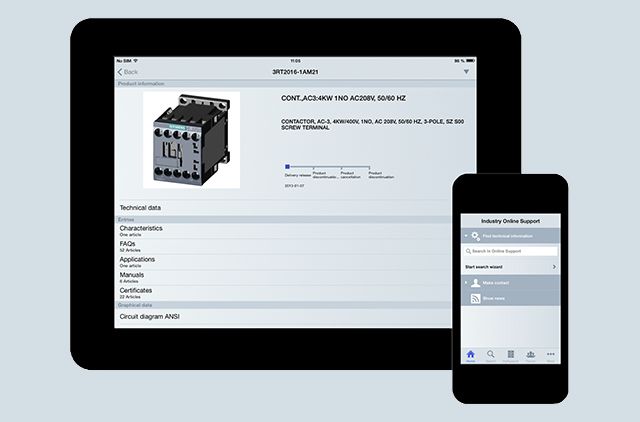

SIRIUS AppsApps for SIRIUS Planning Efficiency Interactive control cabinet The interactive control cabinet shows you a selected product overview, and provides you with useful information and technical data on the relevant components, thus allowing you to plan your control cabinet in advance, efficiently and easily. This saves precious time during project implementation.  Discover our interactive control cabinet 1) at http://www.siemens.com/sirius/cabinet.  1) Now also available as an iPad app in the Apple App Store. Online Support app The Online Support app allows you to access over 300 000 documents on all Siemens Industry products, anywhere and any time. Whether you need help with implementing your project or with troubleshooting, or want to expand your plant or plan a new one, you now have around-the-clock access to FAQs, manuals, certificates, characteristic curves, sample applications and tools, product news and more. The app is available free of charge from the Apple App Store and on Google Play (Android Market) using the search string: "Siemens Industry Online Support".  For more information, see http://www.siemens.com/sirius/support-app.  SIRIUS Innovations DVD - also available as a web app Thanks to the modular design of SIRIUS Innovations, our products are particularly easy to plan for the control cabinet, install and monitor. All the advantages of SIRIUS Innovations are available offline in 9 languages with 3D animations, films and screen recordings of our planning and configuring tools. Ask your sales contact person about the SIRIUS Innovations DVD. The SIRIUS Innovations DVD is now also available as a web app1) (German/English): http://www.siemens.com/sirius/dvd.  SIRIUS Innovations DVD – also available as a web app1) (German/English): http://www.siemens.com/sirius/dvd.  1) Optimized for use with a resolution of 1024 x 768 on iPad and tablet PCs. Energy-efficient control technology:

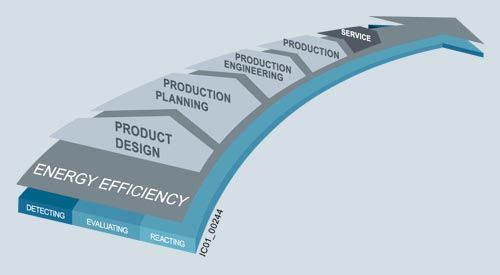

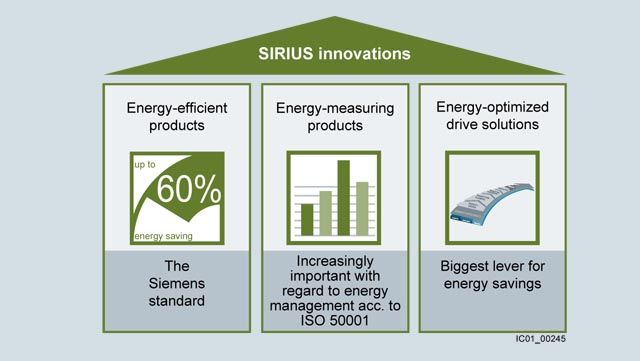

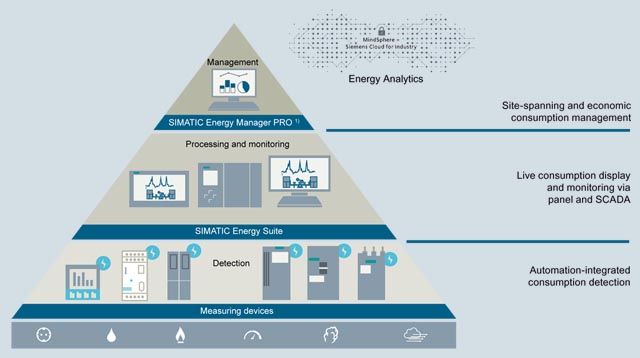

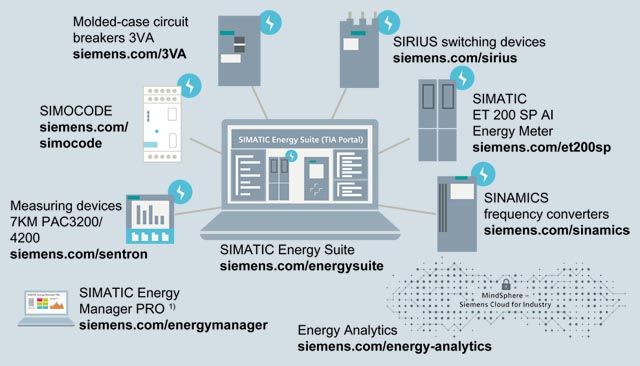

SIRIUS brings down energy costsEnergy management in industry  Overview of the energy management process Be it for plant operators, planners or machine manufacturers: energy-efficient production is a challenge and an opportunity in equal measure. Energy-efficient production as a success factor To utilize potential energy savings, we always keep an eye on the entire product development and production process with our comprehensive portfolio. This is because only a perfect interplay of all components results in highly energy-efficient production. To achieve this, it is important to first create an awareness of existing energy saving potential, to identify optimization options with the aid of a detailed analysis and to evaluate them. Finally, appropriate measures must be implemented (realized). With our integrated portfolio of energy-efficient drive solutions, automation systems and services, you will also achieve maximum energy efficiency, higher productivity and sustainable competitive advantages in your enterprise.  The three pillars of energy efficiency with products from the SIRIUS modular system Energy-efficient products – SIRIUS reduces power loss SIRIUS controls (3RM motor starters, 3RR2 monitoring relays, 3RB3 overload relays, 3RT2 contactors, 3RW soft starters, 3RV2 motor starter protector/circuit breakers and 3RA6 compact starters) are characterized by extremely low intrinsic power loss. This cuts not only energy costs, but also the amount of waste heat in the control cabinet. This then translates to a higher packing density and a reduction in the required cooling performance. Energy-measuring products Energy management can be instrumental in increasing plant productivity and thus bringing about a significant improvement to the competitive ability of a company – in all areas of industry. Energy data acquisition represents an important component of the overall energy data management process. Thanks to transparency right down to the loads, it becomes possible to identify and utilize hidden energy saving potential. With communication-capable SIRIUS industrial controls (SIMOCODE pro V motor management and control devices, 3RR24 monitoring relays, 3RW44 soft starters), you can record energy data from the drive train without any additional outlay. SIRIUS controls help you make energy flows visible. Best drive solutions in terms of energy To optimize energy efficiency of processes, it is not only important to measure the energy flow and to use energy-efficient products. The greatest lever for saving energy comes from closely examining a specific application. For sample applications on the Internet, see http://www.siemens.con/sirius/energysaving. SinaSave energy efficiency tool:  Amortization calculator for energy-efficient drive systems The SinaSave energy efficiency tool determines energy saving potential and amortization periods based on your individual conditions of use and therefore offers practical assistance in making decisions regarding investments in energy-efficient technologies. From SinaSave version 6.0 and higher, the drive systems to be compared and the relevant drive component parameters are displayed graphically. The diverse options for comparing different control types and extensive product combinations for drive solutions for pump and fan applications represent an additional expansion. Our product portfolio encompasses not only SIRIUS controls, but also SIMOTICS motors and SINAMICS converters/inverters, and thus offers a comprehensive range of comparison options - tailored to your requirements. Further information on the amortization calculator for energy-efficient drives is available at: http://www.siemens.com/sinasave Energy management with SIMATIC Energy Suite Energy management, design Integrated energy management SIMATIC Energy Suite A high energy consumption and automated production are typical for many industries. If you want to keep your energy costs under control in the long term and you are already focusing on the digital future, you will equip your plant with integrated energy measuring technology, thus anchoring your energy management in the automation of your production processes – which is where most energy is consumed. SIMATIC Energy Suite as an integrated option for the TIA Portal efficiently links energy management with automation, thus creating energy transparency in the production system. The considerably simplified configuration of energy measuring components from the product families2) SIMATIC, SENTRON, SINAMICS, SIRIUS and SIMOCODE significantly reduces the configuration costs. Thanks to the end-to-end connection to SIMATIC Energy Manager PRO1) or cloud-based Service Energy Analytics, you can seamlessly expand the recorded energy data to create a cross-site energy management system. Companies can therefore additionally satisfy all required economic and energy management aspects – from the purchasing of energy and planning, right up to energy controlling. The advantages at a glance: - Automatic generation of energy management data

- Integration into TIA Portal and into automation

- Simple configuration

Highlights - Simple and intuitive configuration instead of programming

- Automatic generation of the PLC energy program

- Convenient integration of measuring components from the Siemens portfolio and from the portfolio of other vendors

- Integrated into the TIA Portal and automation

- Archiving on WinCC Professional or PLC

- Seamless connection to Energy Manager PRO and Energy Analytics

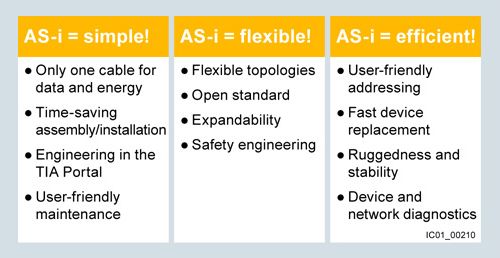

For more information on SIMATIC Energy Suite: http://www.siemens.com/energysuite. 1) SIMATIC Energy Manager PRO is the innovative successor to SIMATIC B.Data. 2) Products from the SIMATIC, SENTRON, SINAMICS, SIRIUS and SIMOCODE product families. For details on the currently supported devices, see http://www.siemens.com/energysuite-hardware. SIRIUS for AS-Interface AS-Interface AS-Interface – the smart communication standard for universal connection of the field level to the control system The AS-Interface (AS-i) – the Actuator-Sensor-Interface, to be more precise – is a smart bus system for the field level that connects all the sensors and actuators in the field to the higher-level control system more simply, flexibly and efficiently than any other. The structure of a complex automation system is not always clear at first glance. The field level in particular, with its large numbers of devices with real-time requirements, needs a clear structure. That is exactly what the AS-i fieldbus delivers - in an AS-i network, up to 62 bus nodes can be connected to the AS-i master and simultaneously supplied with power via a simple two-wire cable – the yellow AS-i cable. The standard here is robust data transmission in a rugged environment with a high degree of protection for the AS-interface.  AS-i from Siemens has everything in its favor - Complete AS-i product range for bus-based standard and safety technology from a single source

- System-wide integration of Siemens AS-i devices into SIMATIC, SINUMERIK, and the TIA Portal engineering framework

- Integration of ASIsafe applications via PROFIsafe into SIMATIC F controllers (for PROFINET/PROFIBUS)

- Quick diagnostics, especially for machine tools - at the slave, centrally via web browser, HMI or TIA Portal

- Central configuration of standard and safety technology in the TIA Portal and in STEP7 Classic - just one engineering framework for controller, AS-i master and safety

- Integration of lower-level AS-i networks into the PCS 7 process control system

- Global spare parts logistics, consulting and service

Engineering in the Totally Integrated Automation Portal (TIA Portal) The TIA Portal – as a key component of TIA – is an innovative engineering framework for all automation tasks. It combines control programming and configuration of visualization, and integrates the parameterization of drives and networks, together with the programming of failsafe applications. The TIA Portal is particularly intuitive to operate. For example, configuring is easy using drag & drop from the hardware catalog, and you get realistic displays of all network nodes and components down to actuator/sensor level. In addition, the engineering framework allows you to get started quickly in safety programming by means of a library with certified safety functions. Device and network diagnostics: - Diagnostics and error signals can also be tracked through all bus hierarchies down to the lowest actuator/sensor level and described in plain text. The basis for this is a realistic depiction of the bus topology concerned.

- The TIA Portal also sets standards where efficiency is concerned. Data from lower-level AS-i networks can be flexibly integrated using drag & drop based on SIMATIC HMI and WinCC. All you need do is "drag" the signal information from any AS-i slave into the control display of an HMI basic panel.

- Furthermore, integrated web servers and diagnostics based on user-specific websites allow the data from all connected AS-i networks to be displayed and integrated into user-specific control concepts (e.g. website for documenting and operating a SIMATIC S7-1200).

Whatever your industry, the TIA Portal allows you not just to work more efficiently, but also to achieve lasting increases in productivity and competitiveness. For more information, see

http://www.siemens.com/as-interface,

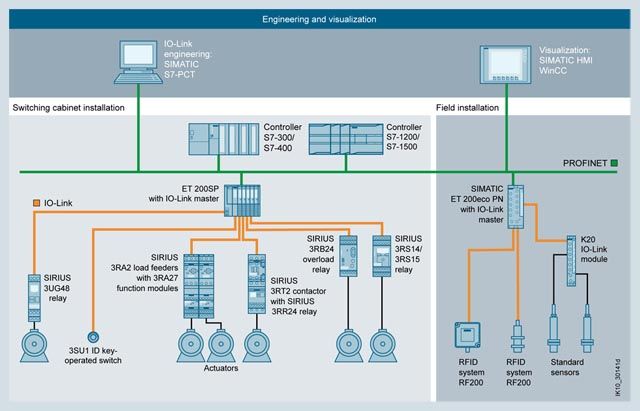

http://www.siemens.com/tia-portal. SIRIUS for IO-Link Engineering and visualization with IO-Link IO-Link – more than just another interface IO-Link is a smart concept for the uniform connection of switching devices and sensors to the control level by means of a low-cost point-to-point connection. The IO-Link communication standard below fieldbus level enables central error diagnostics and localization down to the actuator/sensor level, and facilitates both commissioning and maintenance by allowing parameter data to be dynamically changed directly from the application. The increasing intelligence of field devices and their integration into automation as a whole allow data access down to the lowest field level. The result: greater plant availability and reduced engineering overhead. As an open interface, IO-Link can be integrated into all common fieldbus and automation systems. The advantages of IO-Link at a glance - Engineering в†’ reduced engineering times

- Standardized, open system for greater flexibility (non-Siemens IO-Link devices can be integrated in engineering)

- Uniform and transparent configuration and programming through integrated engineering (SIMATIC STEP 7)

- Freely available function blocks for SIMATIC for user-friendly parameterization and diagnostics, and read-out of measured values

- Efficient engineering thanks to pre-integration of Siemens devices into SIMATIC HMI

- Low error rate in CAD circuit diagram design as a result of reduced control current wiring

- Installation and commissioning в†’ reduced commissioning times

- Faster assembly with minimized error rate as a result of reduced control current wiring

- Space savings in the control cabinet

- Low-cost circuitry where there are several feeders by making unlimited use of existing Siemens components

- Operation and maintenance в†’ greater system availability

- High transparency in the system right down to field level

- Reduction of downtimes and maintenance times through system-wide diagnostics and faster fault correction

- Support for preventive maintenance

- High transparency through integration into energy management systems, reading out of current values and diagnostic signals

- Shorter changeover times, even for field devices, by means of central management of parameters and recipes

Transparency in processes thanks to IO-Link High levels of system availability and data transparency are market requirements that must also be met when connecting innovative control technology to control systems. A systematic diagnostics concept and efficient handling of parameter data are required for this purpose in automation. With the aid of the IO-Link communication standard, a communication link is established between switching device and controller, and this allows data to be exchanged efficiently. Based on a standard cable, it is therefore possible to integrate parameter, process and diagnostic data and measured values into the plant automation with ease. For example, the available diagnostic data allow potential errors to be detected quickly, thus avoiding lengthy plant downtimes. As a consequence of their basic function, such as overload protection (SIRIUS 3RB24), many controls have measured values. The availability of these via IO-Link now allows conclusions to be drawn at an early stage concerning wear and tear in the application. At the same time, the option of parameterizing via IO-Link supports the device not just when parameters concerning operating time are changed, but also when the device is replaced. With spare parts, for example, the parameters can be quickly transmitted to a new device via the communication system. For more information, see

http://www.siemens.com/io-link. SIRIUS Safety Integrated Safety Integrated – safety engineering for machinery and plants Manufacturers and operators of machines must fulfill numerous requirements: reducing costs, improving productivity, and ensuring the safety of machines. The industrial safety technology from Siemens offers innovative and economical solutions for the functional safety of machinery. Machine safety – compliance with directives Before machines or plants can be supplied or operated, they must meet the fundamental safety requirements of the EU Directives. To guarantee conformity with the European Machinery Directive, it is recommended that the correspondingly harmonized European standards EN 62061 or EN ISO 13849-1 are applied. This gives manufacturers and operators legal certainty regarding compliance with both national regulations and the EU Directive. The machine manufacturer uses the CE marking to document compliance with all relevant directives and regulations in the free movement of goods. As the European directives are recognized worldwide, their use is of great help when exporting to other countries. The aim of safety technology is therefore to protect people, machinery and the environment, and to enable compliance with statutory safety requirements The quick and easy way to safe machinery In addition to the statutory regulations governing the protection of people, there are also economic reasons for preventing personal injury and the resulting downtimes, and for protecting machinery and equipment against damage. Safety Integrated benefits machine manufacturers and plant operators in many ways: - Lower costs for hardware, installation and engineering

- Enhanced availability thanks to faster diagnostics and reduced downtimes

The use of modular safety concepts also makes it easier and more economical to modernize your plants. Smart switching devices ensure the functional safety of machines With our SIRIUS Safety Integrated controls, we form a central component of the overall Siemens Safety Integrated concept that is based on Totally Integrated Automation. Whether for reliable detecting, commanding and signaling, monitoring and evaluation, or starting and safe disconnection – SIRIUS Safety Integrated controls provide cost-effective solutions for the safety of your machine or plant. Take SIRIUS 3SK1 safety relays, for example: They are modularly expandable and can integrate compact motor starters, such as the fail-safe SIRIUS 3RM1, very simply via the rear-panel device connector. Or the SIRIUS 3RK3 Modular Safety System - it provides a high degree of functionality as an autonomous safety controller downstream of a standard control, and it also enables smart safety solutions via AS-Interface. The SIMOCODE pro modular motor management system combines all the required protection, monitoring, safety and control functions for motor feeders. It can be connected to fail-safe controllers via PROFIBUS or PROFINET, and it can safely shut down motors in emergency situations.  Controls for safety solutions – SIRIUS Safety Integrated SIRIUS Safety Integrated also solves more complex network-based safety tasks by means of fail-safe communication via standard fieldbus systems such as ASIsafe via AS-Interface and PROFIsafe via PROFIBUS and PROFINET. This opens the door to flexible safety solutions for compact machines or large-scale plants – naturally compliant with current standards up to SIL 3/PL e. A particular highlight - the world's first integrated ASIsafe connection to the distributed I/O ensures even more consistency. With the SIMATIC AS-i F-Links, AS-i networks can be connected quite simply to safety controllers via PROFIsafe via a SIMATIC ET 200SP. Your partner for machine and plant safety With Safety Integrated, Siemens provides the smart answer to constantly increasing requirements regarding functional machine safety as well as for the cost-effectiveness and flexibility of a given system. Our comprehensive drive technology and industrial controls portfolio provides scalable solutions for precisely tailored safety concepts for protecting people, machines and the environment. Our products meet the current safety standards in the industry, including ISO, IEC, NFPA und UL. As a partner for machine and plant safety, Siemens also supports users with functional examples and up-to-date know-how on international standards and directives. In addition to the free TГњV-approved Safety Evaluation Tool for evaluating safety functions in accordance with EN 62061 and EN ISO 13849-1, requirements-based training is available on CE marking, functional safety and risk assessment, and on our Safety Integrated products. For more information, see

http://www.siemens.com/safety-integrated. Application Manual "SIRIUS Safety Integrated", see

https://support.industry.siemens.com/cs/ww/en/view/81366718. Application areas

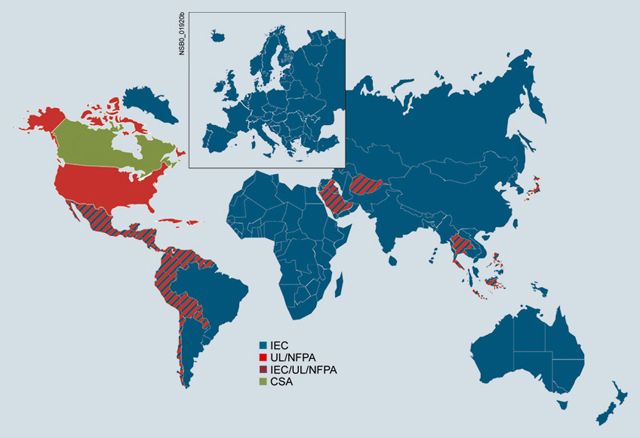

SIRIUS supports you where UL is concerned SIRIUS application areas We support you where UL is concerned Product liability laws in the USA are significantly stricter than in Europe. Anybody wishing to export their products to North America is strongly advised to have them certified to UL standards, particularly where electrical equipment is concerned. We can help you with our comprehensive know-how and broad portfolio of UL-certified low-voltage controls. Who or what is UL? UL (Underwriters Laboratories Inc.®) is one of the world’s leading organizations for testing and certification in the field of product safety. This independent, non-profit making US-based organization was founded in 1894 by American fire insurance groups, with the intention of investigating the fire hazards presented by electrical devices. Today, UL checks and certifies the operational safety of all kinds of materials, components and end products, particularly with regard to the possibility of personal injury and the formation of fires. There are branches in a number of European countries. Detailed information on the US organization as well as contact details for the various European subsidiaries are also available on the Internet at http://www.ul.com. Differences between UL and IEC The IEC standards for the IEC market merely define the minimum safety requirements for a device or system. The technical details relating to how safety requirements are to be implemented in practice a matter for the manufacturer. By contrast, the guidelines for the American market are much more specific. Depending on the standard, the entire process in question may be monitored - from product design and manufacture to application and installation, right through to operation. NFPA79 is the electrical standard for industrial machinery outside the control cabinet. As such it differs from and is the counterpart to the control cabinet standard UL 508A. A UL partner since 1969 Enlisting the expertise of a partner such as Siemens is a wise move for anyone who wishes to avoid unnecessary aggravation and save both time and money. Ever since 1969 our production facility in Amberg, where our entire range of low-voltage controls is developed and produced, has been working closely with Underwriters Laboratories Inc. Right from the product development stage, we take not only EU Directives and IEC guidelines, but also UL standards, into account. This has resulted in a wide-ranging portfolio of UL-certified low-voltage switchgear, controlgear and protection circuit technology. We therefore offer comprehensive know-how on the subject of UL certification, ranging from production down to control panel wiring according to UL standards, which we will be pleased to explain to you within the scope of our application consulting service. Our range of low-voltage controls keeps you on the safe side where UL is concerned, and allows you to assemble UL-compliant control cabinets quickly and easily. Cost-effectiveness in the building and operation of switchgear and control cabinets for North America - Stay flexible for the widest range of solutions and expansions with our comprehensive, coordinated product portfolio, from the infeed of the machine control system to the smallest actuator in the machine.

- Reap the benefits of efficient stock keeping thanks to the universal usability of the products (IEC-UL/CSA).

- Implement a uniform operating and maintenance concept based on our standard system.

- Save space and costs with coordinated product interfaces and compact designs.

- Experience easy, efficient local operation thanks to user-friendliness.

UL-certified SIRIUS products and systems You will find a number of UL-certified products in our IC 10 catalog, such as: - Controls, from motor-protective circuit breakers and starters to contactors and overload relays

- Circuit breakers for plant and transformer protection

- Detecting and command devices

- Power supplies

In catalog LV 16, you will also find a comprehensive selection of components for control cabinets in compliance with UL. You can find information on UL standards, the UL classification and a number of technical particularities of UL on our website. We have summarized the available products and product groups under "Information Material" в†’ "Standards and Approvals". A table lists the UL standards to which products conform and provides references to the corresponding UL reports. For more information, see http://www.siemens.com/applicationconsulting/ul.

|