|

Analytical performance

|

|

Measuring range

|

Internally adjustable

|

|

Detection limit at standardized conditions:

25 °C gas temperature, 1 000 hPa, 1 m effective optical path length, 3 s integration time and constant ambient conditions.

|

O2: 200 ppmv

CO: 0.6 ppmv

|

|

Linearity (under standard conditions)

|

Better than 1%

|

|

Repeatability (under standard conditions)

|

O2: 1% of the measuring range

CO: 0.5 % of the measuring range

|

|

General information

|

|

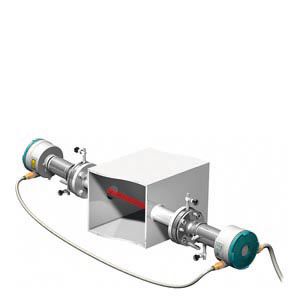

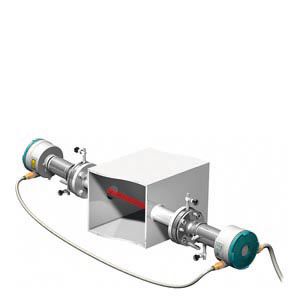

Design

|

Transmitter and detector units, connected by a sensor cable

|

|

Materials

|

- Sensor enclosure: treated aluminium/stainless steel

- Process interface: acid-resistant stainless steel

- Window: hardened borosilicate glass

|

|

Installation

|

In-situ or bypass

|

|

Concentration units

|

ppm, vol. %, mg/Nm3

|

|

Display

|

Digital concentration display (4 digits with floating decimal point)

|

|

Laser protection class

|

Class 1, safe to the eye

|

|

Explosion protection

|

Optionally, according to

- ATEX II 2G Ex de op is IIC T6

ATEX II 2D Ex tD A21 IP65 T85 °C

- FM Class I, II, III Div 1 Groups A, B, C, D, E, F, G T6

FM Class I, Zn 1, AEx d IIC T6

FM Class II, Zn 21, AEx td T85 °C

- XP Class I, II, III Div 1 Groups C, D T6 Ta = 55 °C;

DIP Class II,III Div 1 Groups E, F, G T6 Ta = 55 °C; Class I, Zn 1, Ex d IIC T6 Ta = 55 °C; Zn 21, Ex tD T85 °C Ta = 55 °C

|

|

Design, enclosure

|

|

Degree of protection

|

IP65 according to EN 60529

|

|

Dimensions

|

For each unit (transmitter, detector)

- Diameter: 165 mm

- Length: 357 mm

|

|

Purging tube

|

Length, outer diameter, inner diameter:

340, 48, 44 mm

|

|

Weights

|

|

|

|

6.0 kg

|

|

|

5.2 kg

|

|

|

|

|

|

5.3 kg

|

|

|

Approx. 12 kg

|

|

Connection dimension customer flange

|

DN 50/PN 25, DN 50/PN 40 or ANSI 4"/150 lbs

|

|

Electrical characteristics

|

|

Power supply

|

24 V DC nominal (18 ... 30.2 V DC)

|

|

Power consumption, maximum

|

10 VA

|

|

EMC

|

In accordance with EN 61326-1

|

|

Electrical safety

|

In accordance with EN 61010-1

|

|

Fuse specifications

|

T1.6L250V

|

|

Dynamic performance

|

|

Warm-up time at 20 °C ambient temperature

|

Approx. 15 min

|

|

Response time (T90)

|

Approx. 2 s, depends on application

|

|

Integration time

|

0 ... 100 s, selectable

|

|

Influencing variables

|

|

Variations in ambient temperature

|

< 0.5%/10 K of the measuring range

|

|

Process gas temperature

|

With compensation: < 1 %/100 K of the measuring range

|

|

Variations in atmospheric pressure

|

Negligible

|

|

Process gas pressure

|

O2: With compensation: < 1%/4 000 hPa of the measuring range

CO: Negligible

|

|

Variations in supply voltage

|

Negligible

|

|

Electrical inputs and outputs

|

|

Number of measurement channels

|

1

|

|

Analog outputs

|

2 outputs, 4 ... 20 mA, floating, ohmic resistance max. 660 ?. External isolating power supplies may have to be provided by the customer.

|

|

Analog inputs

|

2 inputs, designed for 4 ... 20 mA, 120 ?

|

|

Digital outputs

|

2 outputs, with switchover contacts, configurable, 24 V/0.5 A, floating, single pole double throw (SPDT)

|

|

Digital input

|

1 input, designed for 24 V, floating, configurable

|

|

Service port

|

Ethernet 10BaseT (RJ-45)

|

|

RS 485 PROFIBUS DPV0 version

|

Two-wire interface, up to 3 Mbit/s, -7 … 12 V

|

|

RS 485 Modbus version

|

Two-wire interface, up to 115 200 bit/s, -7 … 12 V

|

|

Cable to customer interface (not included in standard delivery, ATEX or optional)

|

|

Analog connection cable

(with ATEX configuration: only supplied cables may be used!)

|

10 x 2, with shielding in twisted-pair configuration (depending on type and number of I/Os used)

|

|

PROFIBUS DP connection cable

(with ATEX configuration: only supplied cables may be used!)

|

1 x 2 + 4 (PROFIBUS DP hybrid cable)

|

|

Modbus connection cable

(with ATEX configuration: only supplied cables may be used!)

|

1 x 2 + 3, with shielding in twisted-pair configuration

|

|

Cable length for ATEX configuration

|

3 m

|

|

Conductor cross-section

|

Min. 0.34 mm?

|

|

Cable diameter

|

8 ... 12 mm or 13 ... 18 mm

|

|

Minimum bending radius ATEX-PROFIBUS

|

110 mm

|

|

Sensor cable (not included in standard delivery, ATEX or optional)

|

|

Sensor cable type configuration

|

4 x 2, with shielding, in twisted-pair configuration

|

|

Conductor cross-section

|

Min. 0.34 mm?

|

|

Cable sheath

|

PUR (polyurethane)

|

|

Dimensions

|

- Diameter: 11 mm

- Length: up to 25 m

|

|

Minimum bending radius

|

ATEX: 85 mm

|

|

Climatic conditions

|

|

Ambient temperature range

|

- -20 ... +55 °C during operation (additional solar radiation not permissible!)

- -40 ... +70 °C during transport and storage

|

|

Temperature range on the sensor side of the process interface (connection plate)

|

-20 ... +70 °C

|

|

Atmospheric pressure

|

800 ... 1100 hPa

(for ATEX and FM version)

|

|

Humidity

|

< 100 % rel. humidity

|

|

Measuring conditions

|

|

Measurement path

|

0.3 ... 8 m (other lengths: please contact Siemens)

|

|

Process gas pressure, temperature

|

- O2: 900 ... 1 100 hPa, 0 … 600 °C

- O2: 700 … 5 000 hPa, 0 … 200 °C

- CO: 700 … 2 000 hPa, ?20 … 300 °C

- CO: 800 … 1 200 hPa, ?20 … 700 °C

|

|

Dust load

|

The influence of a high dust load is complex, and depends on the optical path length and particle size distribution.

|

|

Purging

|

|

Purging gas

|

- Oxygen (for O2 and CO applications)

- Instrument air (for CO applications)

|

|

|

O2 application: Purity better than 99.7 % in order to achieve full performance. For oxygen measurements, an O2 content < 0.01 vol. % in the purging gas is recommended.

|

|

|

< -10 °C, condensation on the optics must be avoided

|

|

Sensor purging

|

|

- Max. overpressure in the sensor

|

500 hPa

|

- Purging gas temperature on sensor side

|

0 ... +55 °C

|

|

|

O2 application: When commissioning a sensor enclosure previously filled with air: 3 ... 5 l/min (for at least 15 min), subsequently: at least 0.25 l/min

|

|

Purging on the process side (optional)

|

|

- Pressure at purging gas inlet

|

2 000 ... 8 000 hPa

|

|

|

Dependent on process gas pressure, process gas velocity, dust load, moisture, etc. up to max. 50 l/min

|