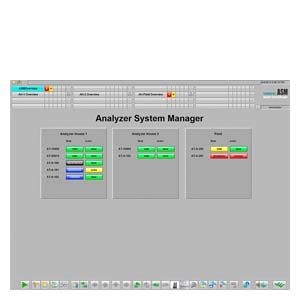

General informationInformation of the analyzers is collected over the communications network and saved in the central ASM database for further analysis. ASM is operated from a PCS 7 environment, and it is possible to navigate between overview screens, device-specific displays and general functions. Overview of analyzers in a plant ASM has the following function modules for each analyzer for performing operator control and monitoring tasks:

View of the maintenance module Examples of generated reports Further functions are:

ValidationOne of the core functions of ASM is checking the analyzers for reliability of the measured values. Two different methods of measurement are available for recording the values, namely the reference sample method and the line sample method. The resulting values can be checked using different evaluation methods (based on ASTM D3764 or deviation). The objective of the validation is to recognize fluctuations and deviations with respect to a comparison value, and to thus permit a statement to be made on the reliability and drift of the measurement. Method of measurement: Reference sample method The analyzer is disconnected from the process gas, and a reference gas connected for measurement. The composition of this reference gas has previously been specified in the "Reference bottle management" of the ASM. ASM uses these values to determine the deviation between the measurement and the reference. Method of measurement: Line sample method With this method, a gas sample is extracted from the stream of sample gas to the analyzer, and analyzed in the laboratory. The resulting measured values are passed on to ASM and compared with the analyzer's measured values. With this method, the analyzer need not be disconnected from the process gas, and permanently remains available for the process measurement. Evaluation based on ASTM D3764 Based on the international standard ASTM D3764, the results are checked using various statistical methods, including standard deviation, Dixon outlier test, and systematic error. Evaluation using deviation method Limit values are defined for this evaluation: the warning limit and the control limit. Simple rules are used to define how the reliability of the measurement is to be assessed when these limits are violated. For example, it can be defined that a single violation of the limit can be tolerated, but that repeated violation is an impermissible condition. View of the validation module |

| Каталог 2018 | Каталог 2017 | Каталог 2016 | Каталог 2015 | Каталог 2014 | Каталог 2013 | Каталог 2012 | Сертификат | Контакты | Карта сайта | Поиск |